In the fast-paced world of packaging, efficiency, precision, and cost-effectiveness are essential factors for success. Vertical Form Fill Seal (VFFS) machines have become integral to modern packaging systems, particularly in industries where speed and accuracy are critical. These machines offer a range of benefits that improve packaging processes and enhance product output. This article will explore what VFFS machines are, how they work, and why they are a game-changer for businesses seeking to optimize their packaging operations.

What is a Vertical Form Fill Seal Machine?

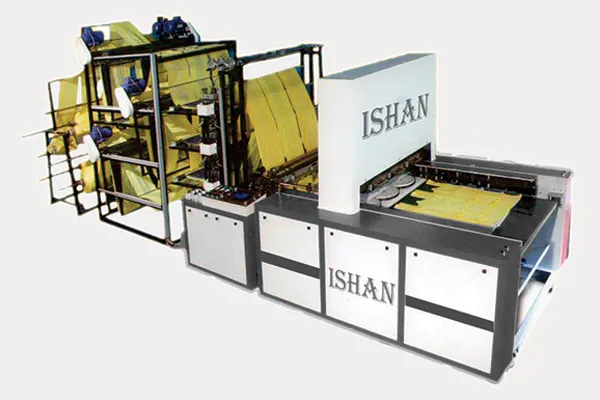

A Vertical Form Fill Seal (VFFS) machine is a type of packaging equipment designed to form, fill, and seal bags automatically. The process begins with the machine forming a bag from a roll of flat film, which is then filled with the product and sealed to ensure it is securely enclosed. The VFFS process is highly versatile and can handle a wide range of products, including powders, liquids, grains, and solid items. Moreover, vertical form fill seal machine manufacturers offer customized solutions to meet specific packaging requirements across different industries, such as food, pharmaceuticals, and chemicals.

How Does a VFFS Machine Work?

The operation of a VFFS machine can be broken down into several key steps:

- Film Unwinding: The machine starts with a roll of flat film material, which is fed into the machine.

- Forming the Bag: The film is then formed into a tube shape using a set of rollers. A set of mechanical jaws shapes the tube into a pouch, creating the bottom seal of the bag.

- Filling: The product is dispensed into the bag through a filling station. Depending on the product type, this station may include options for portion control, liquid filling, or powder dispensing.

- Sealing: After the product is inserted, the top of the bag is sealed using heat and pressure to create a secure closure.

- Cutting and Discharge: The machine then cuts the formed bag from the tube of film and discharges it onto a conveyor for further processing or transport.

Key Benefits of Vertical Form Fill Seal Machines

VFFS machines offer numerous advantages, making them a popular choice in the packaging industry. Here are some of the key benefits:

1. Improved Efficiency and Speed

VFFS machines are designed to operate at high speeds, allowing manufacturers to package large quantities of products in a short amount of time. This increased throughput can significantly improve the overall efficiency of the packaging process, reducing labor costs and increasing production output.

2. Customization and Versatility

One of the biggest advantages of VFFS machines is their versatility. These machines can accommodate various packaging formats, such as stand-up pouches, pillow bags, gusseted bags, and more. Moreover, VFFS machines can be configured to handle different types of products, whether they are powders, liquids, or solid items. Customizations can be made to suit specific product needs, ensuring flexibility in the packaging process.

3. Space-Saving Design

Unlike horizontal packaging systems, VFFS machines take up less floor space as they operate vertically. This compact design is particularly beneficial for businesses with limited space in their facilities. The efficient use of space allows for better organization and can even help reduce the overall footprint of the packaging line.

4. Reduced Waste

VFFS machines are designed to minimize film wastage, as the precise cutting and sealing mechanisms ensure that bags are produced with minimal excess material. This reduction in waste contributes to cost savings and helps companies operate more sustainably by reducing the environmental impact of packaging operations.

5. Enhanced Product Protection

The sealing capabilities of VFFS machines provide a tight and reliable seal, ensuring that the products inside the bags are protected from contamination, moisture, and air. This is especially important for food products, pharmaceuticals, and other items that require secure packaging to maintain their quality and shelf life.

Applications of Vertical Form Fill Seal Machines

VFFS machines are used in a wide variety of industries, including:

- Food Packaging: For packaging snacks, grains, coffee, and frozen foods.

- Pharmaceuticals: For packaging tablets, capsules, and powders.

- Chemical and Industrial Products: For packaging fertilizers, detergents, and other bulk products.

In each of these sectors, VFFS machines improve packaging efficiency and ensure that products are securely sealed, helping businesses meet both regulatory requirements and consumer demands.

Conclusion

Vertical Form Fill Seal machines have revolutionized the packaging industry by offering a highly efficient, flexible, and cost-effective solution for a wide range of products. With their ability to handle various bag types and product formats, VFFS machines are an essential tool for companies looking to streamline their packaging process. The combination of speed, precision, and reduced waste makes them an invaluable asset in any modern production environment. Whether you’re packaging food, pharmaceuticals, or industrial products, a VFFS machine can significantly enhance the quality and efficiency of your operations.